The Elephant and the Straw

Posted on Thursday, June 26, 2014

Four common coaxial cable throughput misconceptions and how rethinking

the board and the coaxial cable interconnect can help ease the pressure.

(Could a direct-to-board solution be right for you?)

The constant expectation for all handheld and embedded devices is that the next generation model will be richer in features and more compact in size. Oh yes, and it must be smaller and deliver higher data/frequency throughput performance.

More and more, the limiting factor stifling the realization of near instantaneous performance is not the speed and power of the microprocessor, but the data interconnect throughput. As a customer of ours once said, “…can you push an elephant through a straw?”

What is often needed in these next generation cases is micro-miniature coaxial cable, along with fully shielded, microscopic termination. But how?

You might suppose barriers to incorporating custom micro coaxial cables and high-performance direct-to-board terminations include inherent higher cost, fragility of the microscopic termination, long lead times, and minimum order quantities. But these are common misconceptions.

Misconception #1: Direct-to-board interconnect solutions cost more.

This is the most common misconception. In reality, planned accordingly, direct-to-board terminations can yield higher signal performance, reduce lead-times, and cost less than incorporating “custom connector solutions” into the assembly.

Misconception #2: It’s hard to find R&D interconnect manufacturers willing to entertain initial low volumes to vet unproven designs, when only one design will eventually materialize into production volumes.

Custom micro-miniature or micro coaxial cables need to be manufactured to precise specifications while delivering higher data/frequency throughput performance. However, when companies such as HSI have their own fine-wire extrusion capabilities, and its ability to incorporate its high-performance dielectric material (VP90 ePTFE), the game changes. Combine HSI’s ability to customize fine wire extrusion, its VP90, and direct to board terminations with no minimum order quantities and short lead times, and you can expect a unique and superior outcome on the other end of the conversation when considering a custom direct-to-board solution.

Misconception #3: You do not know who could manufacturer a micro-miniature interconnect solution so, you need to invest in your own microscopic termination, equipment and staff.

Also not true. As a value added partner, if you can send us gerber (dxf) files then HSI can manufacture and stuff PC boards or flex circuits, or if you prefer to consign the boards, we can terminate our coaxial cable to complete the solution. Simply send us the files, consign us the boards, and we will do the rest.

Misconception #4: Direct-to-board interconnects are inherently fragile.

Sure, there are some lower budget solutions that are less rugged, but if your application requires some ability to stand-up to regular flexure, HSI has proprietary strain relief processes which ruggedizes the direct-to-board fine wire termination.

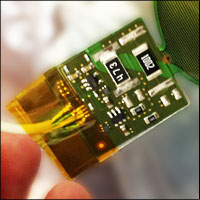

This direct-to-board micro coaxial termination

helped a sensor company get to market fast with a robust solution.

Custom micro-coaxial cable and direct-to-board interconnect solutions may not be for everyone, however, HSI is positioned to resolve any engineering and market pressures.