The Importance of Next-Generation Interventional Catheter Assemblies has Never Been Greater

Posted on Tuesday, November 18, 2014

An Industry Under Pressure

As hospitals and medical device manufacturers face mounting pressure from insurers, consumers, and governmental reformers to decrease their operating costs while increasing quality of care, the importance of next-generation, interventional catheter assemblies has never been greater. As interventional catheter assemblies are manufactured faster and cheaper, they are inherently manufactured in lower cost country (LCC) manufacturing facilities unsuitable for medical device manufacturers. Oftentimes, these supply chains are also less suitable to support advanced technological approaches and materials.

Devil in the Details

Interventional catheter assemblies are used in a variety of endoscopy, renal, diagnostic imaging, and ablation applications. A critical component of these devices (especially when they’re intended to be processed, sterilized and reused), is the micro coaxial cable inside. Each interventional catheter assembly may contain a variety of micro miniature coaxial cables intended to carry signals, power, and imagery during a procedure. These micro miniature coaxial cables are precisely wrapped with a dielectric (commonly known as Teflon®) and more recently expanded PTFE or ePTFE (made by, among others, W.L. Gore as is known as GORE-TEX®, and High Speed Interconnects higher performing alternative to GORE-TEX™ called VP90™). These micro miniature coaxial cables are then further processed using medical grade materials and microscopically terminated to high density pitches of less than 0.175mm. Imagine now, that these tiny cables are packaged to be small enough to fit into a human artery. HSI’s state-of-the art manufacturing capabilities control, with precision, both thin-wall and high-density requirements and can manage overall diameters – which are (frankly) incredible.

Expertise for the Future

HSI’s expertise with “puffing up” or “puffing down,” if you will, the electrical and mechanical characteristics of its micro miniature coaxial cable, makes them a leader in solving for interventional catheter assembly solutions. Achieving balance between air and other molecules to perfect signal integrity while keeping the cable flexible and robust is essential and often overlooked by manufacturers lacking the proper expertise. As doctors and researchers strive to go deeper into smaller and smaller vessels of the body, the pressure to miniaturize coaxial cable assemblies increases exponentially.

So if you’re seeking a high-performance extruder with fine wire termination capabilities for your next single-use or reusable medical device, we invite you to reach out to our experts at sales@highspeedint.com to develop your next interventional catheter assembly.

Speed is Not the Only Critical Requirement for Next-Generation Systems

Posted on Monday, August 25, 2014

Next-generation systems will always be expected to be smaller, lighter and faster. But engineers also face the challenges of full integration. Previously spec’d oversized, heavy, and slow interconnect solutions inside increasingly higher-density systems wreak havoc. So the need for robust, miniaturized high-speed interconnect solutions has never been greater.

Back to the Drawing Board

Next-generation engineers are forced to redesign system platforms to meet market expectations, but equally as important, they must redesign their interconnects to be smaller, lighter, faster, more stable and crush resistant - regardless of constant torsion, flexure, pressure, bend radiuses, or temperature.

HSI Zeros-in on the Ultimate Miniaturized Interconnect Solution

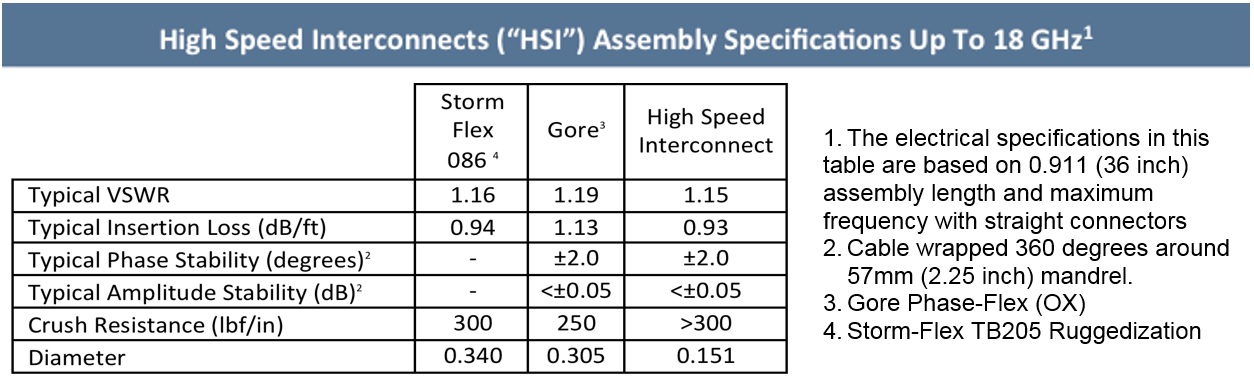

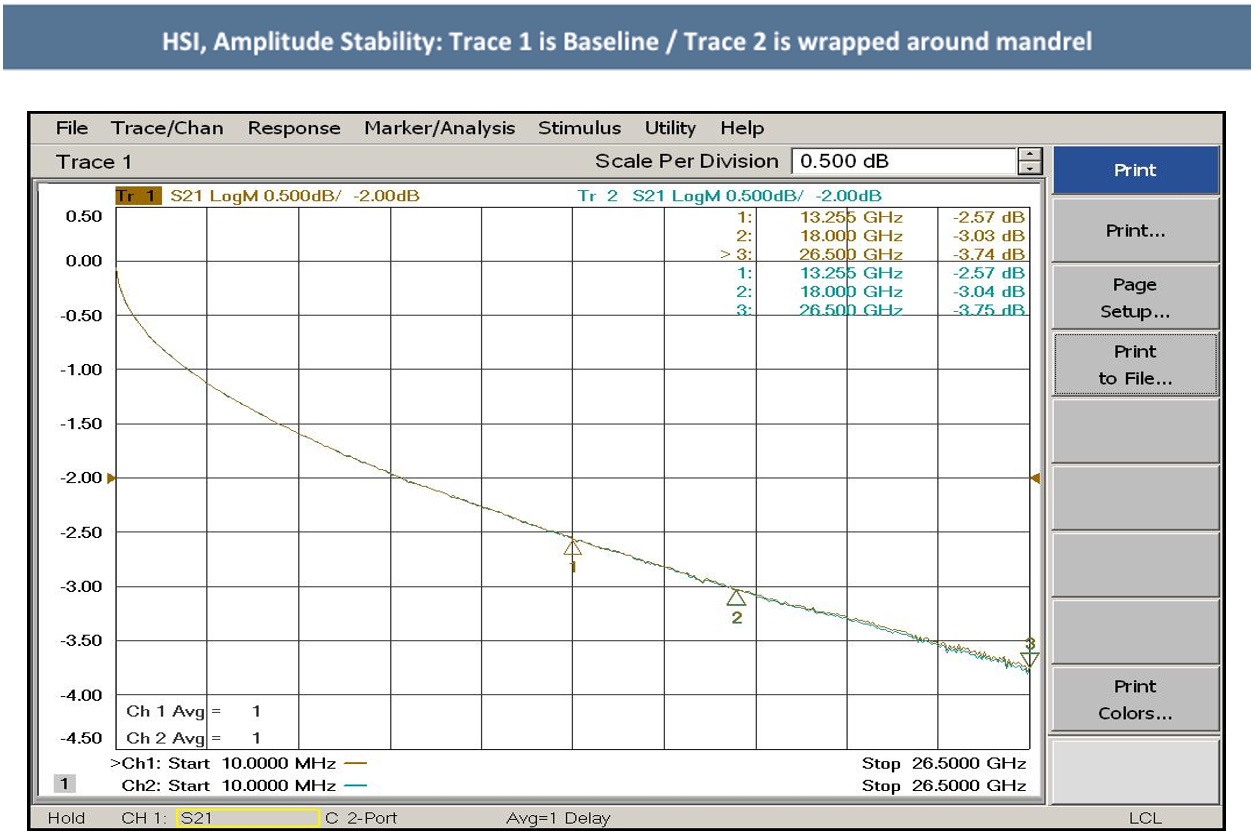

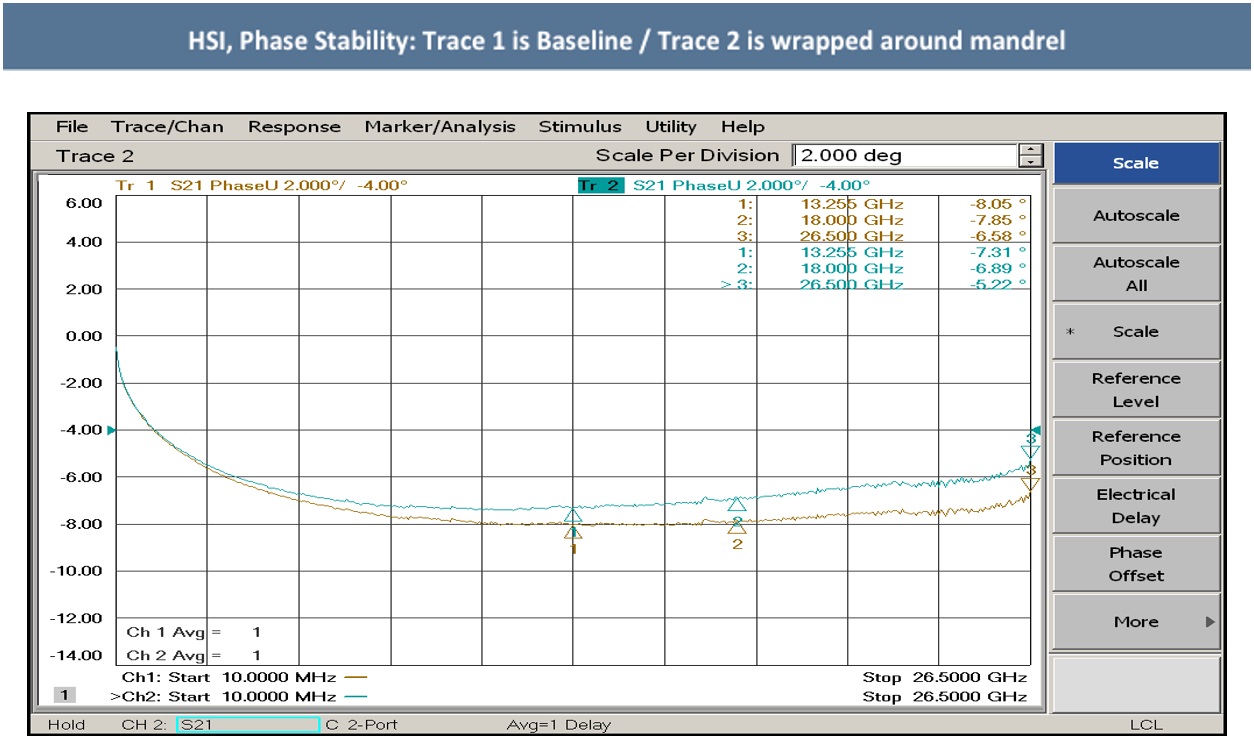

In the chart below, HSI compares its 24 gauge, 18 GHz coaxial cable assembly with two competitors. You will notice the HSI solution dominates the competitors’ VSWR, insertion loss, and phase stability when wrapped tight around a 2.25-inch mandrel. In addition, HSI’s interconnect solution is incredibly crush resistant and significantly smaller in diameter.

As you can see, HSI’s miniaturized interconnect solutions are commonly selected by leading OEM’s for their exceptional electrical and mechanical performance. There will be more to come on this and other HSI capabilities in the next posting. In the meantime if you have an interconnect challenge, contact us to see how we can solve your high performance custom cable assembly requirement.

The Elephant and the Straw

Posted on Thursday, June 26, 2014

Four common coaxial cable throughput misconceptions and how rethinking

the board and the coaxial cable interconnect can help ease the pressure.

(Could a direct-to-board solution be right for you?)

The constant expectation for all handheld and embedded devices is that the next generation model will be richer in features and more compact in size. Oh yes, and it must be smaller and deliver higher data/frequency throughput performance.

More and more, the limiting factor stifling the realization of near instantaneous performance is not the speed and power of the microprocessor, but the data interconnect throughput. As a customer of ours once said, “…can you push an elephant through a straw?”

What is often needed in these next generation cases is micro-miniature coaxial cable, along with fully shielded, microscopic termination. But how?

You might suppose barriers to incorporating custom micro coaxial cables and high-performance direct-to-board terminations include inherent higher cost, fragility of the microscopic termination, long lead times, and minimum order quantities. But these are common misconceptions.

Misconception #1: Direct-to-board interconnect solutions cost more.

This is the most common misconception. In reality, planned accordingly, direct-to-board terminations can yield higher signal performance, reduce lead-times, and cost less than incorporating “custom connector solutions” into the assembly.

Misconception #2: It’s hard to find R&D interconnect manufacturers willing to entertain initial low volumes to vet unproven designs, when only one design will eventually materialize into production volumes.

Custom micro-miniature or micro coaxial cables need to be manufactured to precise specifications while delivering higher data/frequency throughput performance. However, when companies such as HSI have their own fine-wire extrusion capabilities, and its ability to incorporate its high-performance dielectric material (VP90 ePTFE), the game changes. Combine HSI’s ability to customize fine wire extrusion, its VP90, and direct to board terminations with no minimum order quantities and short lead times, and you can expect a unique and superior outcome on the other end of the conversation when considering a custom direct-to-board solution.

Misconception #3: You do not know who could manufacturer a micro-miniature interconnect solution so, you need to invest in your own microscopic termination, equipment and staff.

Also not true. As a value added partner, if you can send us gerber (dxf) files then HSI can manufacture and stuff PC boards or flex circuits, or if you prefer to consign the boards, we can terminate our coaxial cable to complete the solution. Simply send us the files, consign us the boards, and we will do the rest.

Misconception #4: Direct-to-board interconnects are inherently fragile.

Sure, there are some lower budget solutions that are less rugged, but if your application requires some ability to stand-up to regular flexure, HSI has proprietary strain relief processes which ruggedizes the direct-to-board fine wire termination.

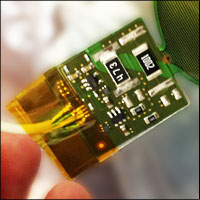

This direct-to-board micro coaxial termination

helped a sensor company get to market fast with a robust solution.

Custom micro-coaxial cable and direct-to-board interconnect solutions may not be for everyone, however, HSI is positioned to resolve any engineering and market pressures.